We are proud sponsors of the SAPPMA 2025 pipelines of progress initiative

We are proud sponsors of the SAPPMA 2025 pipelines of progress initiative

We are proud sponsors of the SAPPMA 2025 pipelines of progress initiative

We are proud sponsors of the SAPPMA 2025 pipelines of progress initiative

These are high-precision components manufactured using injection molding processes to create standard HDPE pipe fittings. These fittings are formed in molds, giving them uniform shape, smooth internal surfaces and excellent dimensional accuracy. They are typically used to connect HDPE pipes and redirect flow especially at angles, branches or changes in diameter. The fittings are available in PN10 and PN16, ranging from DN50mm to DN630mm.

Durable HDPE seamless bends designed for smooth directional flow with minimal pressure loss.

We specialize in a wide range of services, including HDPE pipeline solutions, HDPE pipe lining, Groundwater Solutions, Mineral Exploration.

Custom-made HDPE fittings tailored for complex piping configurations and high-performance applications.

Steel backing rings used to reinforce flanged joints and ensure strong, stable connections.

HDPE stub ends used with backing rings to create robust flange joint connections in piping systems.

High-strength fittings that use heat fusion for secure, long-lasting pipe connections.

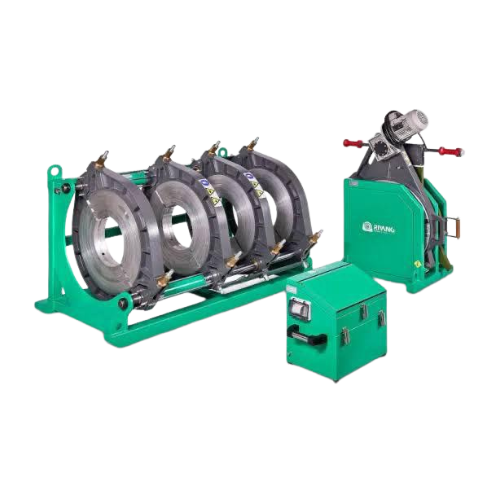

Advanced welding machines designed for precise, efficient butt fusion of HDPE pipes and fittings.

Heavy-duty valves engineered for controlling flow in industrial fluid systems with reliability and ease.

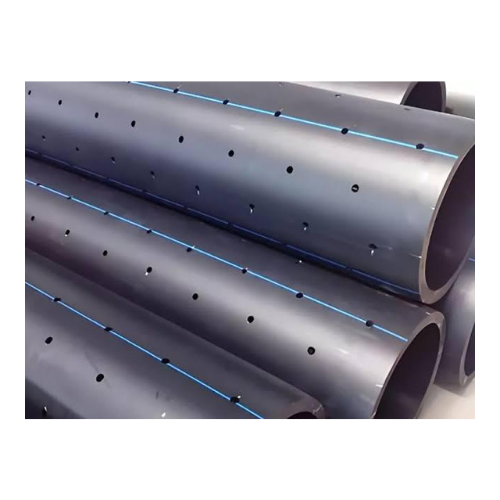

Custom plastic pipe perforation services for applications like drainage, irrigation, and filtration systems.

These are strong, flexible and corrosion-resistant piping systems widely used in water supply, mining and drainage infrastructure.

Stay informed with industry insights, product updates, and innovative HDPE solutions, subscribe to the Arrant Wise newsletter and be the first to know what’s new.